Laser Marking

Laser marking is the ideal alternative when a permanent mark with fine detail and rapid turnaround is required. Bloss can reproduce the finest details of an intricate corporate logo or the smallest lettering and numbers on the head of a titanium bone screw. Our lasers have the capability to mark on cylindrical surfaces, perform automatic serialization, and mark standard bar codes and 2D Matrix I.D. bar codes. We can identify product per Mil-STD-130 and AS478. Laser marking is cost effective while offering a highly legible mark.

Laser marking on anodized products removes the anodized coating in the marking area, revealing the base metal color. Stainless steel products can be processed to create black or dark brown marking with a smooth finish. Titanium products can similarly be processed for a smooth final finish with markings in gold, blue, black, or silver.

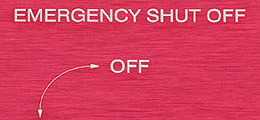

Bloss lasers parts form a variety of industries. Orthopedic implants and surgical instruments, automotive parts, promotional products, electronics components, control panels, and plumbing fixtures are just a few of the items that we regularly process.